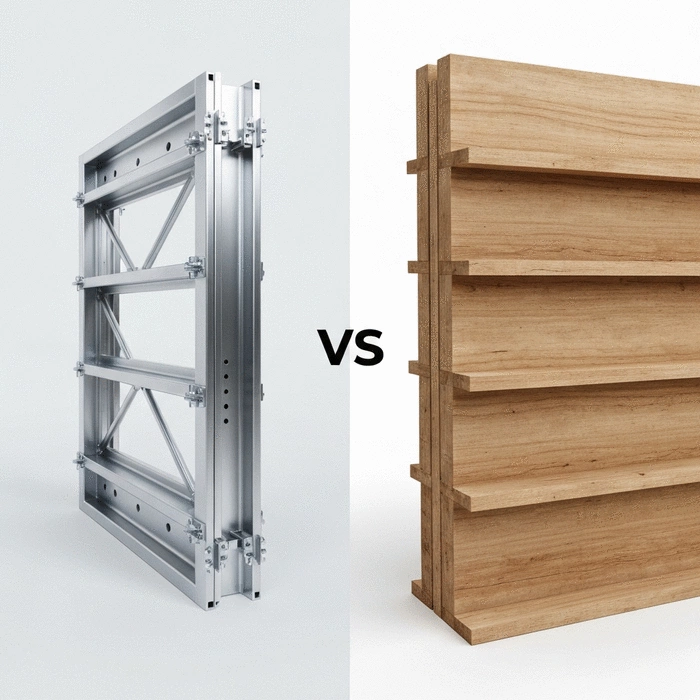

Aluminium vs Timber Formwork: A Comparison

Posted on: 2025-12-11

By: Liam Marston

When evaluating formwork systems, understanding the trade-offs between aluminum and timber can make all the difference for your project's success. What are the key factors that will influence your decision? Let's uncover the essentials.

What You Will Learn

- Aluminum formwork is lightweight, modular, and designed for quick assembly, leading to faster construction timelines.

- Timber formwork is a traditional option that is readily available and offers customization, but often requires more setup time.

- Key comparison factors include cost, installation efficiency, and long-term performance of each formwork type.

- Understanding the pros and cons of each system helps align your choice with the specific demands of your construction project.

Aluminum vs. Timber Formwork: Key Comparison Factors

This comparison highlights the defining characteristics and usability of aluminum and timber formwork across critical construction project dimensions.

Aluminum Formwork

- ✓Efficiency: Rapid assembly/disassembly, significantly reduces construction time.

- ✓Durability: High strength, reusable for multiple projects, less maintenance.

- ✓Precision: Better finish and structural integrity.

- −Customization: Standardized sizes may limit design flexibility for complex shapes.

- −Initial Cost: Higher initial investment.

Timber Formwork

- ✓Availability: Readily available and often less expensive initially.

- ✓Customization: Easily cut and shaped, highly adaptable to complex designs.

- ✓Familiarity: Traditional choice with extensive historical usage among teams.

- −Efficiency: Requires more time for setup and takedown, slower construction.

- −Durability: Shorter lifespan, requires more maintenance.

Understanding Aluminum Formwork and Timber Formwork

As a construction engineer, I’ve seen the evolution of formwork systems over the years. Understanding the difference between aluminum formwork and timber formwork is crucial for any construction project. These materials not only influence the quality of the build but also impact efficiency, cost, and sustainability.

Defining the Basics: What is Aluminum Formwork?

Aluminum formwork is a modern solution designed for concrete casting that uses lightweight, modular panels. The system is engineered for quick assembly and disassembly, allowing projects to progress faster. With its reusable design, aluminum formwork is not only efficient but also contributes to reducing waste on site. Reports such as this comparative study on formwork systems highlight how aluminum formwork significantly reduces construction time and labor costs due to its modular nature and ease of handling.

- Modular panels for easy customization

- High durability and strength

- Significantly reduces construction time

Many builders, including those I’ve worked with, find that this system enhances workflow efficiency. The design flexibility allows structures to be tailored to various architectural needs, making it a go-to choice for modern construction projects.

Defining the Basics: What is Timber Formwork?

Timber formwork, on the other hand, has been a traditional choice in construction for decades. Composed mainly of plywood or lumber, it is often favored for its availability and the ease of working with the material. However, timber formwork tends to require more time to set up and take down, which can prolong project timelines. A study on conventional formwork methods delves into the specifics of timber formwork, detailing its common applications and limitations, particularly concerning its reusability and setup complexity.

- Readily available materials

- Familiarity among construction teams

- Less initial investment compared to aluminum

While timber can be a cost-effective option, it’s essential to weigh its benefits against the long-term performance and sustainability of aluminum formwork. As someone who emphasizes technical precision in construction, I often advocate for evaluating both systems to determine the best fit for each project.

Key Comparison Factors Between Aluminum and Timber Formwork

When deciding between aluminum and timber formwork, several key factors come into play. Understanding these can save time and money, while ensuring project quality.

- Cost: Initial and lifecycle expenses

- Performance: Strength and durability

- Installation efficiency: Time and labor requirements

Evaluating these factors helps clarify which formwork system will best meet the needs of your construction project. Let’s dive deeper into these comparisons to make an informed decision.

Pro Tip

When choosing between aluminum and timber formwork, consider the long-term sustainability of your choice. While aluminum formwork may have a higher initial cost, its reusability and durability can lead to significant savings over multiple projects. Investing in aluminum can enhance workflow efficiency and reduce waste, making it a more sustainable option in the long run.

Making the Right Choice: Aluminum vs Timber Formwork

When it comes to selecting the appropriate formwork for your construction project, understanding the nuances between aluminum and timber formwork is essential. Each material brings its unique strengths and weaknesses to the table. So, how do you decide which is best suited for your specific needs? Let's break it down.

As someone who has spent years working with aluminum formwork systems, I can tell you that the choice often hinges on several key factors. By weighing the pros and cons of each type, you can better align your decision with your project goals and outcomes!

Weighing the Pros and Cons Based on Project Needs

Both aluminum and timber formwork have distinct advantages and disadvantages that can influence your project timeline and budget. Here’s a closer look:

- Aluminum Formwork

- Lightweight yet strong, enabling quick assembly

- Reusable for multiple projects, enhancing cost-effectiveness

- Less maintenance required over time

- More precise, offering better finish and structural integrity

- Timber Formwork

- Readily available and often less expensive initially

- Highly customizable to fit complex designs

- Traditional choice with extensive historical usage

- Requires more maintenance and has a shorter lifespan

Choosing between these materials should also take into account the specific requirements of your project. For example, if you're focusing on a high-rise building that demands rapid construction and durability, aluminum formwork might be your best bet. On the other hand, for smaller, more intricate projects, timber's customization and flexibility can shine.

Customization and Flexibility of Formwork Systems

Customization is a crucial factor when evaluating formwork options. Aluminum formwork, while excellent for speed and reusability, may not offer the same level of adaptability as timber. Here’s how the two compare:

- Aluminum Formwork

- Standardized sizes may limit flexibility in design

- Less suited for highly custom or unconventional shapes

- Timber Formwork

- Can be easily cut and shaped to fit unique structures

- Highly adaptable to various design specifications

Ultimately, the material you choose will depend on your project’s demands. Are you prioritizing speed and efficiency, or do you need to accommodate complex designs? Each project is unique, and the right formwork choice will set the stage for success. Furthermore, this research on formwork selection provides a deeper dive into the decision-making process, considering factors like project scale, environmental concerns, and overall economic impact.

Frequently Asked Questions (FAQs)

1. What are the primary advantages of aluminum formwork?

Aluminum formwork offers lightweight, modular panels that allow for quick assembly and disassembly, significantly reducing construction time. It is highly durable, reusable across multiple projects, requires less maintenance, and provides superior precision for a better finish and structural integrity.

2. Why might timber formwork be preferred over aluminum in some cases?

Timber formwork is often preferred for its lower initial cost, ready availability, and high customization capabilities. It can be easily cut and shaped to accommodate complex and unique designs, making it ideal for projects that require significant design flexibility.

3. Which formwork type is more sustainable in the long run?

While aluminum formwork has a higher initial cost, its extensive reusability and durability make it a more sustainable option over multiple projects. Its long lifespan and minimal maintenance requirements contribute to reduced waste and a smaller environmental footprint compared to timber, which has a shorter lifespan and higher maintenance needs.

4. How does each formwork type impact construction timelines?

Aluminum formwork significantly reduces construction time due to its rapid assembly and disassembly process, leading to faster project completion. Timber formwork typically requires more time for setup and takedown, which can extend project timelines.

5. What are the cost considerations for both aluminum and timber formwork?

Aluminum formwork generally involves a higher initial investment. However, its reusability and efficiency can lead to lower lifecycle costs. Timber formwork has a lower initial cost but may incur higher long-term expenses due to its shorter lifespan and greater maintenance requirements.

Recap of Key Points

Here is a quick recap of the important points discussed in the article:

- Aluminum Formwork: Offers modular panels, high durability, and significantly reduces construction time.

- Timber Formwork: Composed of readily available materials, it is familiar to teams but may take longer to set up and has a shorter lifespan.

- Cost Comparison: Consider both initial and lifecycle expenses when choosing between the two systems.

- Performance Factors: Assess strength, durability, and installation efficiency to determine the best fit for your project.

- Customization: Timber allows for more flexibility in design compared to standardized aluminum panels.

Have you considered how the choice of formwork can dramatically impact your construction planning? A

Have you considered how the choice of formwork can dramatically impact your construction planning? A

Did you know that utilizing modular aluminium formwork can significantly reduce construction time an

Did you know that utilizing modular aluminium formwork can significantly reduce construction time an

When considering new technologies in construction, the potential to enhance efficiency often lies in

When considering new technologies in construction, the potential to enhance efficiency often lies in