Preventive Maintenance Benefits

- ✓Enhances longevity

- ✓Reduces downtime

- ✓Ensures site safety

- ✓Preserves structural integrity

- ✓Reduces repair costs

- ✓Optimizes material usage

Unlock expert insights on aluminium formwork systems and concrete casting workflows. Subscribe for cutting-edge technical guidance.

Posted on: 2025-12-10

By: Liam Marston

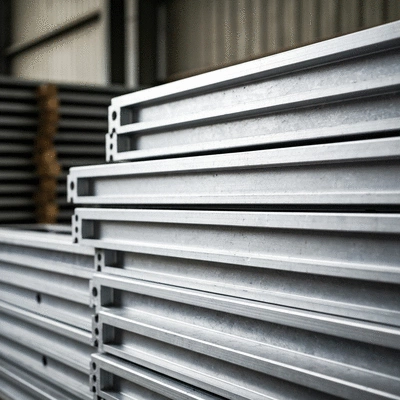

What if investing in preventive maintenance could save your construction projects from costly delays and enhance safety on-site? Understanding the critical nature of maintaining aluminium formwork systems is essential for every construction professional. This article delves into the practices that can transform your workflow and ensure top-notch results.

Preventive maintenance is crucial for aluminium formwork systems, offering significant benefits in longevity, cost efficiency, and safety compared to reactive approaches.

Maintaining aluminium formwork systems is essential for ensuring longevity and efficiency on construction sites. With over a decade of experience in the field, I’ve seen firsthand how preventive maintenance can drastically improve project outcomes. Let’s explore why preventive maintenance is crucial and how it can impact your construction workflow.

Preventive maintenance is the practice of regularly inspecting and caring for your formwork systems to prevent unexpected failures. This approach not only helps in extending the lifespan of aluminium formwork but also minimizes the likelihood of costly repairs. By investing time in maintenance, you're ensuring your team can focus on what they do best—building!

Ultimately, prioritizing preventive maintenance saves both time and resources, allowing your project to proceed smoothly and efficiently. For a comprehensive guide on maintenance and support, you can refer to The Ultimate Guide to Aluminium Formwork Maintenance and Support.

Despite its importance, maintaining aluminium formwork systems can come with challenges. For instance, some teams might struggle with identifying the right maintenance schedules or the required tools. Additionally, environmental factors such as humidity and temperature fluctuations can affect the performance of your systems over time.

Addressing these challenges head-on can lead to better maintenance outcomes and ultimately improve your project’s success.

Regular maintenance strategies greatly influence the structural integrity of aluminium formwork systems. When you implement a thorough maintenance plan, you’re not just protecting your investment; you’re enhancing the overall quality of your projects. With a proactive approach, you can prevent minor issues from escalating into major problems, significantly improving cost efficiency. Detailed technical procedures for maintaining construction elements can be found on the GSA's Historic Preservation Technical Procedures page.

In the long run, investing in preventive maintenance translates to higher-quality construction outcomes, which is the ultimate goal for every builder and contractor!

To maximize the effectiveness of your aluminium formwork maintenance, consider incorporating digital tracking tools. These tools can help you schedule inspections, log maintenance activities, and monitor performance metrics in real-time. This proactive approach not only streamlines your workflow but also provides valuable data that can guide future maintenance strategies.

Regular maintenance of aluminium formwork systems is not just a good habit; it's an essential practice that brings numerous long-term benefits. By integrating a structured maintenance plan, you can enhance the lifespan of your formwork, improve safety on-site, and significantly reduce costly repairs down the line. As I always emphasize, a well-maintained system is a reliable system!

Here are some key reasons why prioritizing maintenance is a game-changer for your projects:

By adopting these best practices, you set the foundation for smoother project execution and better quality outcomes. It’s all about being proactive rather than reactive!

The advantages of consistent maintenance extend beyond immediate safety and functionality. Think about the long-term value that comes from maintaining your aluminium formwork systems. Regular upkeep can lead to:

These benefits not only impact the current project but create a ripple effect that can elevate your business’s standing in the industry.

At Aluminium Formwork Online, we believe that sustainable practices are vital. Implementing environmentally-friendly maintenance strategies not only conserves resources but also aligns with modern construction standards. For more information on sustainable procurement and general best practices in construction, you can explore resources like the FHWA's Buy America Q&A General.

By prioritizing sustainability, we not only contribute to the well-being of our planet but also position our businesses as forward-thinking and responsible.

To measure the effectiveness of your maintenance efforts, establishing performance metrics is crucial. Here are some metrics you can track:

By evaluating these metrics regularly, you can adjust your strategies and ensure that your maintenance practices are driving the desired outcomes.

Now that we've covered best practices for aluminium formwork maintenance, it’s time to put these insights into action! A solid maintenance plan is key to safeguarding your investments and ensuring project success.

For those looking to deepen their understanding of aluminium formwork maintenance, I recommend exploring the following resources:

These resources can equip you with the knowledge needed to tackle maintenance challenges effectively and confidently.

To streamline your maintenance efforts, I’m excited to offer a downloadable maintenance checklist! This tool is designed to help you track maintenance tasks, schedule inspections, and ensure compliance with safety standards. A simple checklist can make a huge difference in keeping your formwork in top condition!

Make sure to utilize this resource to enhance your maintenance efforts and keep your projects running smoothly. You can find the checklist right here on our site!

Here is a quick recap of the important points discussed in the article:

Have you considered how the choice of formwork can dramatically impact your construction planning? A

Have you considered how the choice of formwork can dramatically impact your construction planning? A

Did you know that utilizing modular aluminium formwork can significantly reduce construction time an

Did you know that utilizing modular aluminium formwork can significantly reduce construction time an

When considering new technologies in construction, the potential to enhance efficiency often lies in

When considering new technologies in construction, the potential to enhance efficiency often lies in